TorqueMaster Original springs were introduced in 1994. Wayne Dalton described their new product as “an innovative counterbalance system for garage doors that is easier, faster, and safer to install than other systems on the market.” It is believed that the invention of the counterbalance that safely conceals the springs within a steel tube was a first of its kind.

In 2007, Wayne Dalton made manufacturing changes and introduced the TorqueMaster Plus spring system. After more than 30 years, TorqueMaster remains a leading counterbalance system for builders and new garage doors.

As of September 11, 2025, Wayne Dalton is no longer manufacturing TorqueMaster Original (TM | TM1) Replacement Springs or parts.

The End Bracket/Winding Tool (PN# 282339/282340) is the most commonly requested replacement part due to frequent breakage. The worm gear and drive gear (PN# 282335) within the End Bracket are common failure points and are no longer replaceable.

TorqueMaster Original Spring Differences

There were two generations of the TorqueMaster Original Style between 1994 - 2007.

1994 - Early 2000’s

- Inside Diameter: 0.721”

- Wire Type: ASTM A229 oil-tempered spring steel

- Strength Source: quench-and-temper heat treatment

- Result: solid, predictable performance, baseline ~10k cycles

Early 2000’s - Present

- Inside Diameter: 0.650”

- Wire Type: ASTM A228 music wire

- Strength Source: extreme cold drawing + stress relief

- Result: higher tensile strength and 25-30% longer cycle life (~13k cycles)

Because of this design change, doors installed from the 1990’s through the early 2000’s may be difficult to match exact specifications.

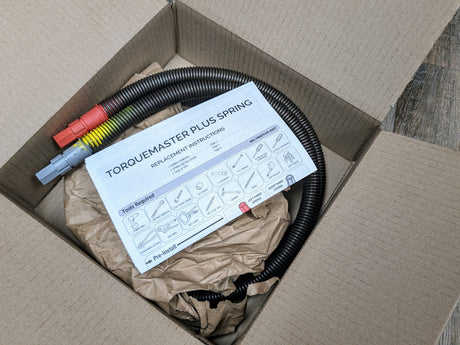

Recommended Replacement Option

If you have a TorqueMaster Original Spring that requires replacement the best solution would be to purchase the Single Spring Upgrade Spring Kit or Double Spring Upgrade Kit. These kits include everything needed to convert from the TorqueMaster Original system to the TorqueMaster Plus spring system.

For additional details, refer to the Converting to TorqueMaster Plus | Learn blog post, which explains the required components and system changes in detail.

Spring Equivalency Reference Tables

Below are equivalency tables provided to assist with accurate selection when converting spring sizes.

For Door Heights of 6'0" thru 7'0"

|

0.721” ID |

0.650” ID |

Counterbalance/Lift Weight |

|

0.135 X 40.55 |

0.133 X 40.23 |

60 - 62.5 LBS |

|

0.143 X 45.79 |

0.137 X 42.85 |

65 - 67.5 LBS |

|

0.146 X 47.22 |

0.140 X 44.20 |

70 - 72.5 LBS |

|

0.149 X 48.81 |

0.143 X 45.72 |

75 - 77.5 LBS |

|

0.154 X 51.02 |

0.146 X 47.38 |

80 - 82.5 LBS |

|

0.154 X 49.94 |

0.146 X 46.01 |

82.5 - 85 LBS |

|

ALL SPRINGS ABOVE 85 LBS OF COUNTERBALANCE/LIFT WEIGHT WILL HAVE AN INTERNAL ROD. |

||

|

0.157 X 52.85 |

0.151 X 49.70 |

85 - 87.5 LBS |

|

0.160 X 54.81 |

0.154 X 51.59 |

90 - 95 LBS |

|

0.163 X 56.90 |

0.157 X 53.62 |

95 - 100 LBS |

|

0.167 X 60.79 |

0.160 X 55.77 |

100 - 105 LBS |

|

0.169 X 61.45 |

0.164 X 59.74 |

105 - 110 LBS |

|

0.172 X 63.91 |

0.164 X 57.14 |

110 - 115 LBS |

7'3" thru 8'0" Door Heights

|

0.721” ID |

0.650” ID |

Counterbalance/Lift Weight |

|

0.135 x 45.08 |

0.129 X 42.11 |

55 - 57.5 LBS |

|

0.139 X 47.87 |

0.133 X 44.76 |

60 - 62.5 LBS |

|

0.143 X 50.91 |

0.137 X 47.67 |

65 - 67.5 LBS |

|

0.146 X 52.51 |

0.140 X 49.18 |

70 - 72.5 LBS |

|

0.149 X 54.28 |

0.143 X 50.87 |

75 - 77.5 LBS |

|

0.154 X 56.81 |

0.146 X 51.19 |

80 - 82.5 LBS |

|

ALL SPRINGS ABOVE 85 LBS OF COUNTERBALANCE/LIFT WEIGHT WILL HAVE AN INTERNAL ROD. |

||

|

0.157 X 58.85 |

0.151 X 55.36 |

85 - 87.5 LBS |

|

0.160 X 61.03 |

0.154 X 57.48 |

90 - 95 LBS |

|

0.163 X 63.36 |

0.157 X 59.74 |

95 - 100 LBS |

|

0.167 X 67.71 |

0.160 X 62.15 |

100 - 105 LBS |

|

0.169 X 68.45 |

0.164 X 66.58 |

105 - 110 LBS |

|

0.172 X 71.20 |

0.164 X 63.67 |

110 - 115 LBS |