There are two reliable ways to tell—by home build year and by how the springs are wound.

If your home was built after 2007, you almost certainly have TorqueMaster Plus.

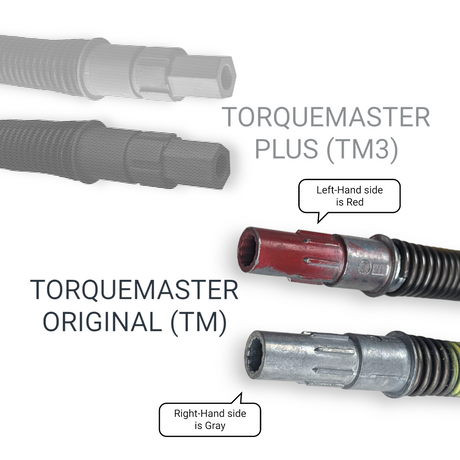

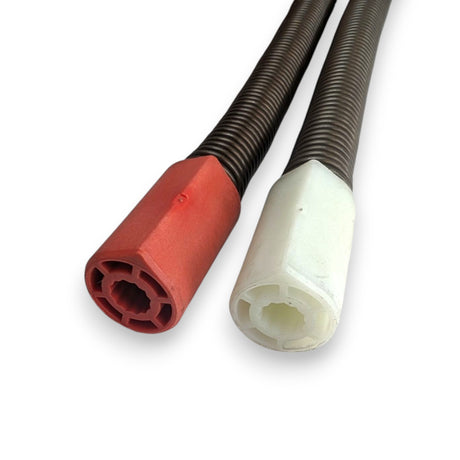

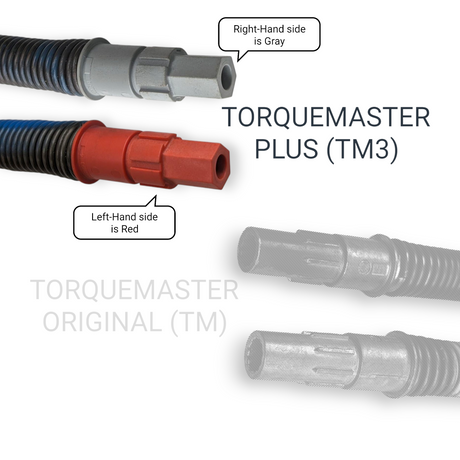

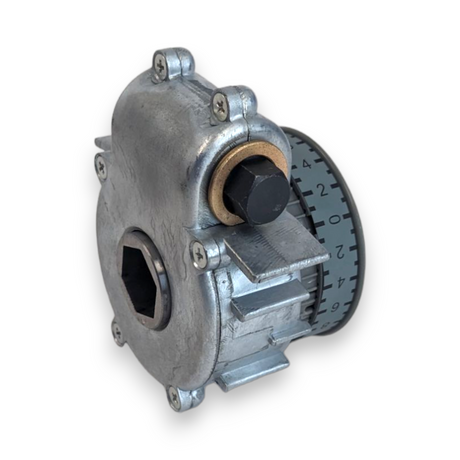

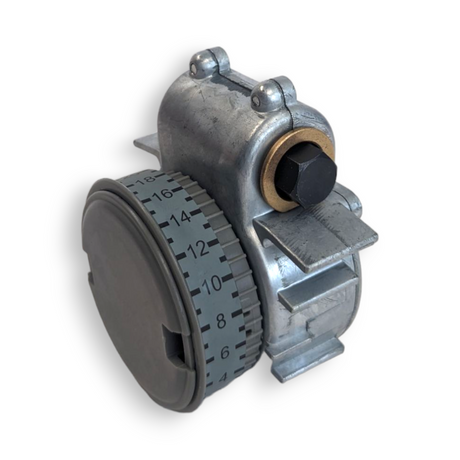

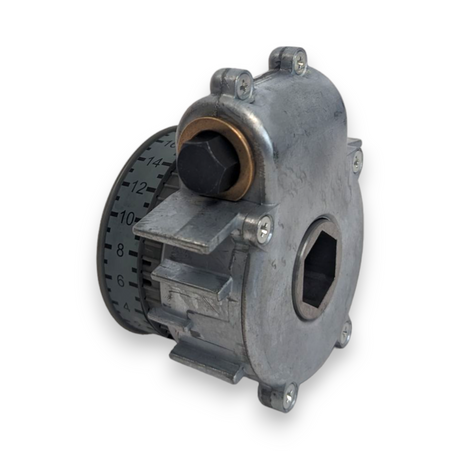

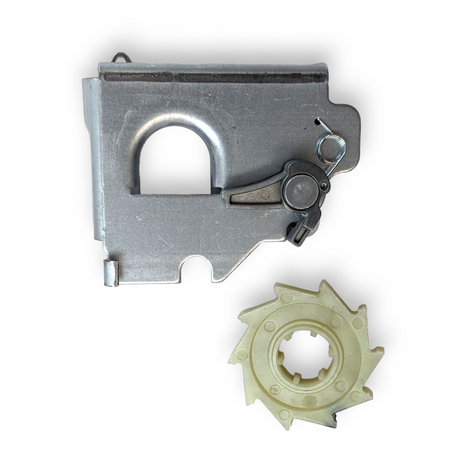

Visually, the systems are easy to distinguish:

- TorqueMaster Original uses a winding bracket with numbered markings and is wound using a 7/16" bolt head.

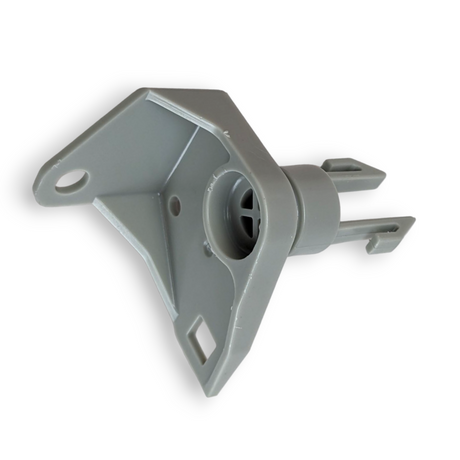

- TorqueMaster Plus has an end bracket where the springs protrude through, and the system is wound using a 5/8" ratchet socket and wrench.

If you’re still unsure, a quick photo of the end bracket is usually enough for us to identify the system and point you to the correct replacement parts.